In October 2000 the NanoSIMS passed all the tests that were specified in our contract at the CAMECA factory in Paris. Now it was finally time to pack up the entire instrument and ship it to St. Louis. It first went by air cargo to New York and then by truck to St. Louis.

The entire shipment consisted of four huge wooden crates. The largest one alone had a gross weight of almost 3 tons as can be seen on this shipping label.

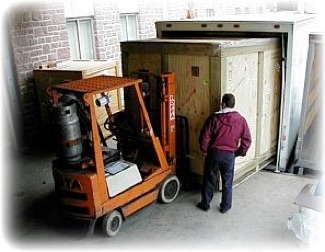

On December 1st, 2000, the crates arrived in two trucks at the Physics Department. Luckily, it was not snowing that day. It was not so easy to get the boxes out of the truck and the whole operation took all morning. The fork lift did not actually lift the boxes, but rather pulled them inch by inch onto the loading dock.

As always, when some hard work needs to be done, there were plenty of spectators who were ready to take pictures at any moment.

In the front are Olga Pravdivtseva, Sachiko Amari, Scott Messenger, Ernst Zinner and Bob Walker.

Getting the boxes into the building was not much easier than getting them out of the truck. We had not really measured everything before, but somehow everything fit just perfectly. At this point our biggest concern was not to drop the crates and break the instrument at the last moment. That’s why we lifted the boxes always only a few inches off the ground and everything proceeded very slowly.

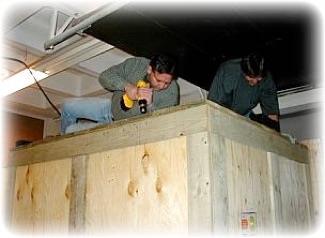

Once inside we started to open the crates. The biggest one (shown here) had one box inside the other for extra protection. The shipping company really did a great job and it took us two days to get everything taken apart.

Tim Smolar and Frank Stadermann on top of the crate.

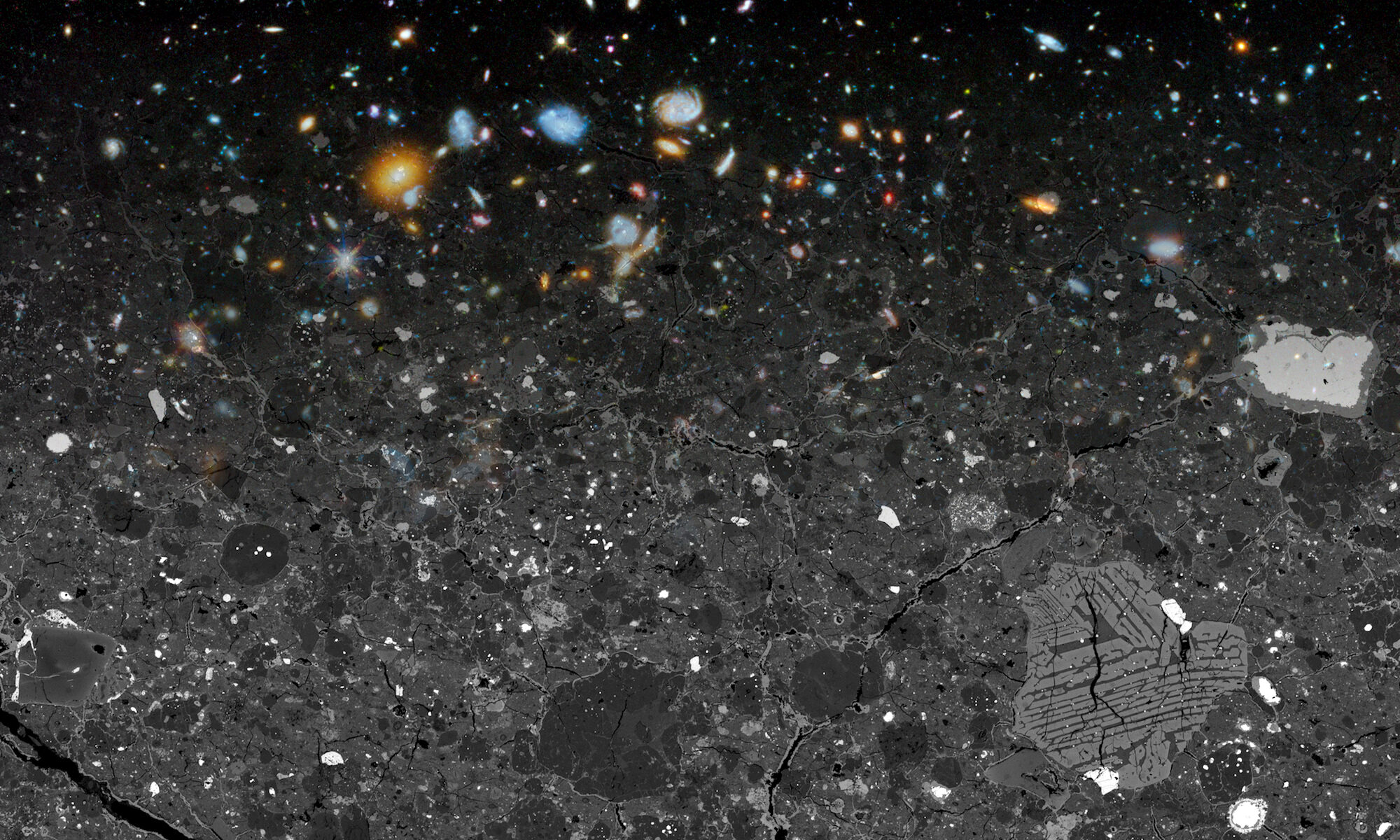

Finally: A first glimpse at the NanoSIMS. Everything looked fine.

It got more interesting, though: The cargo elevator that was supposed to bring the instrument to our lab on the 4th floor malfunctioned (for the first time in years) at exactly the moment when the 2-million-dollar instrument was loaded into it. The elevator made it up to the 4th floor, but ended up about 1 foot too high and then completely stopped doing anything. Tim is wondering what to do next.

A little later, an elevator repairman starts some routine maintenance service down in the elevator shaft, totally unaware of the 3 ton load above his head. Here, Tim is trying to yell to him down there to alert him of the problem.

Eventually, of course, everything comes to a happy conclusion and the machine is unloaded at the right level.

The main part of the instrument is at its ultimate destination in the lab. At this point, the airlock part and the ion sources are still missing.

With the help of a fork lift, the airlock system is being transported to the right location. This ‘small’ component weighs 250 kg and is really awkward to maneuver around.

In a similar way, the ion source assembly is being moved to its place. Danny, our fork lift driver, did a great job navigating his big machine through our lab without hitting anything. He said this was the first time he has gotten instructions like “one inch forward” or “up one quarter-inch” in all the time he has been driving fork lifts.

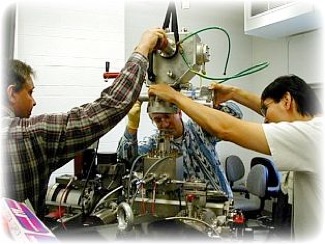

Tim Smolar (left) and Eric Inazaki (right) help Bernard Vautier of CAMECA to position the sources on the primary column of the NanoSIMS.

Almost three years after signing the contract with CAMECA© and several more years after we first became interested in the new ion probe design we finally have a good reason to celebrate. The first commercial NanoSIMS has arrived at the Laboratory for Space Sciences.